It’s been a while since I last posted. Many things been going on, and a few things have changed. We’ve gone from late summer, through the fall, into winter, and now into a new year,

Summer in Maine goes by way too fast. We had a beautiful meadow of wildflowers next to the house and shop, an area that I don’t mow. This was the first year in many that we’ve had bluebirds, also lots of butterflies, bees and hummingbirds. I had planted native wildflowers which helped draw the birds and insects. The most spectacular blossom was the orange butterfly milkweed.

Fall was short and spectacular, my favorite season. The maples, as usual put on a great show. This is one behind the garden shed.

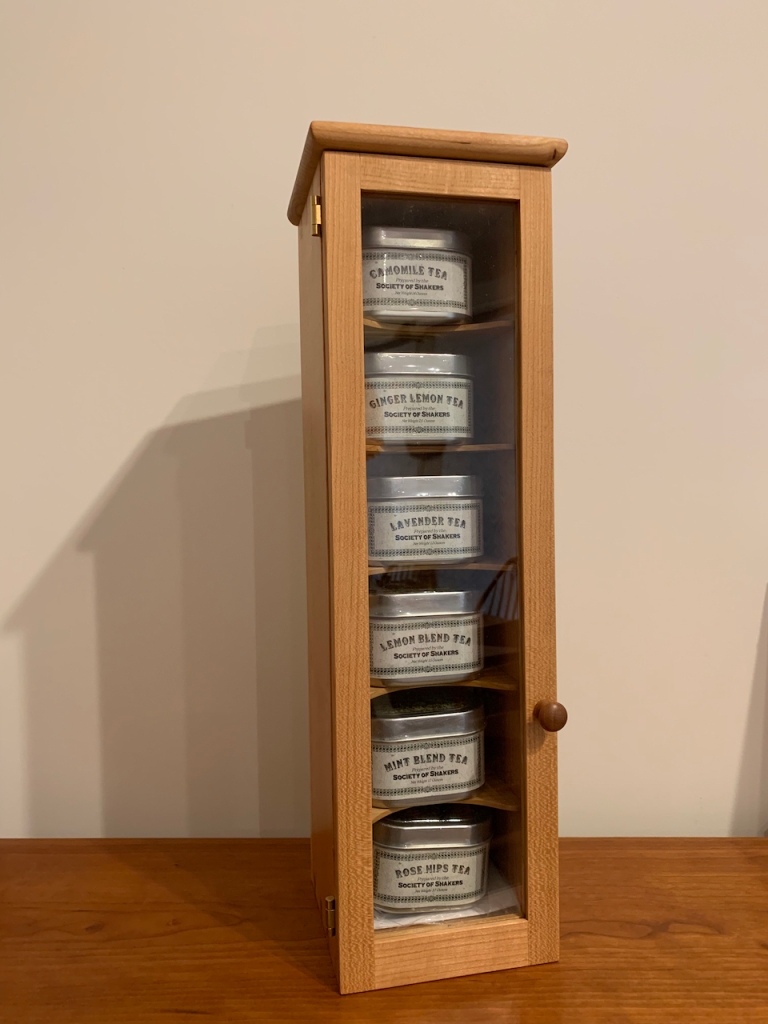

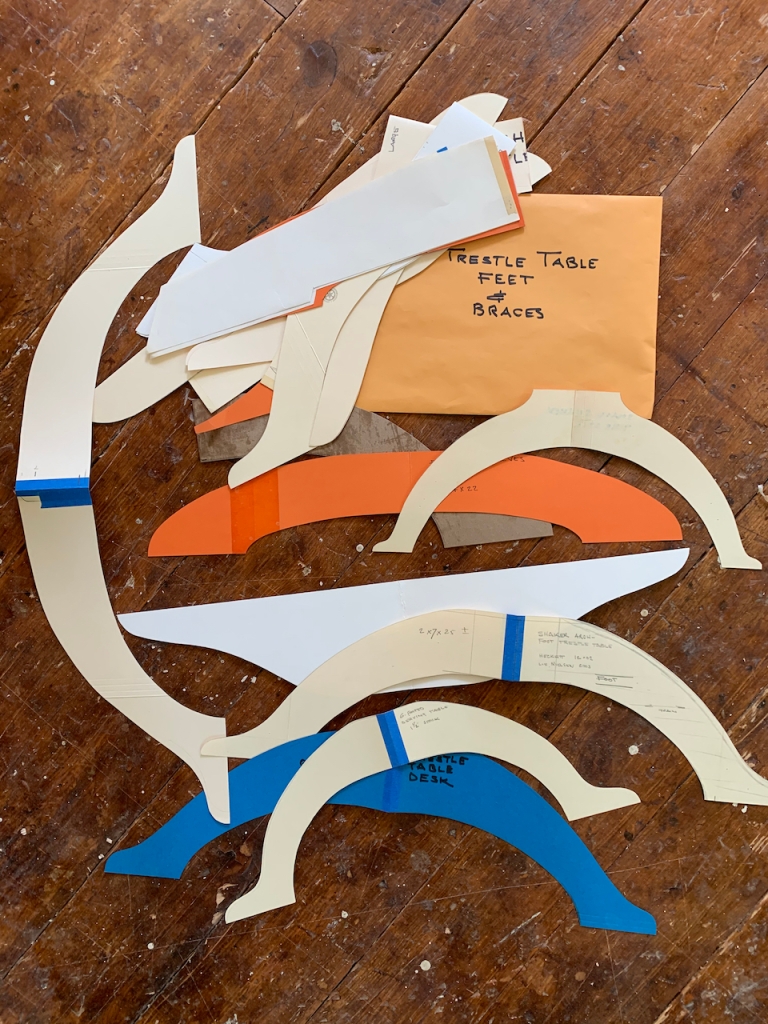

The shop work kept me busy throughout the last half of the year. One of the most interesting and challenging projects was the restoration of a Sabbathday Lake Shaker table. It had had one corner smashed in transit, and needed major surgery: the ends of two rails and the upper portion of the leg, where the mortises are located. Matching old, worn wood, with several different finishes is not an easy job, but with patience and practice, it turned out pretty well.

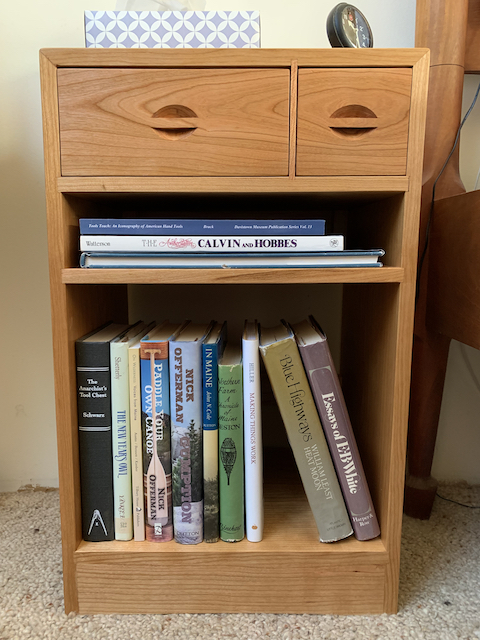

I also made a few Shaker round stands, a music stand, started a tall custom cabinet, and reproduced a cedar garden bench.

The new Oneida SuperCell was hooked up and connected to six machines. Since I had positioned the blast gates under the ceiling to save space, I made wooden extension handles, with magnets to make the gates easy to reach, and stay securely closed when not open.

The high point of the fall was the visit of 20 Danish woodworkers (in two shifts, so sorry I don’t have a picture of the afternoon group). They all brought small projects for “show and tell.” It was so interesting to see the imaginative design work going on in Denmark.

The low point of the season was when I slipped and fell on a wet sidewalk, and broke my wrist. After the bone had mended, and the cast was removed, the doctor mentioned that it would take another 3-9 months for the torn muscles and tendons to return to normal.

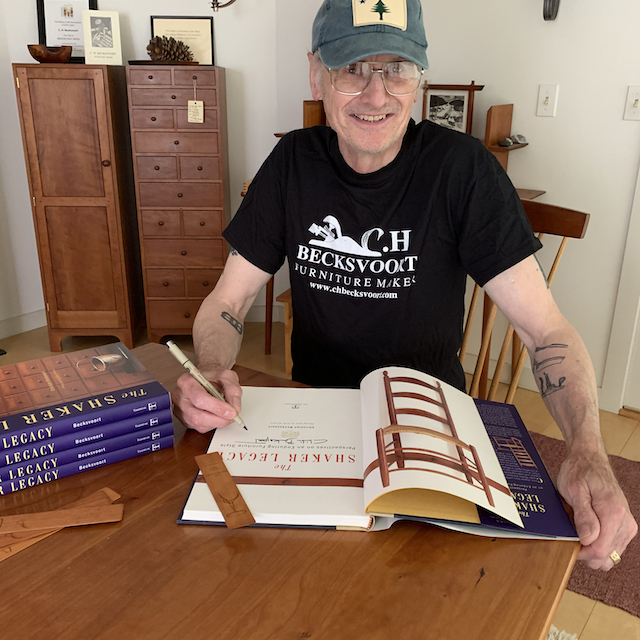

I had fully intended to retire and close the business by the end of 2022. That was more than doable before the accident, with only three more projects to complete. Now however, it will drag on into 2023. Retiring does not mean that I will stop woodworking. On the contrary, I plan on lots of new designs that I’ve been waiting to produce, given some free time. I will continue to write for Fine Woodworking magazine. I’m also working on a new book, once the right hand is functional again.

Happy New Year.

C.H. Becksvoort © 2023